Filament Extrusion Machines

Using fused filament fabrication to deliver diverse options, streamlined production and optimal results

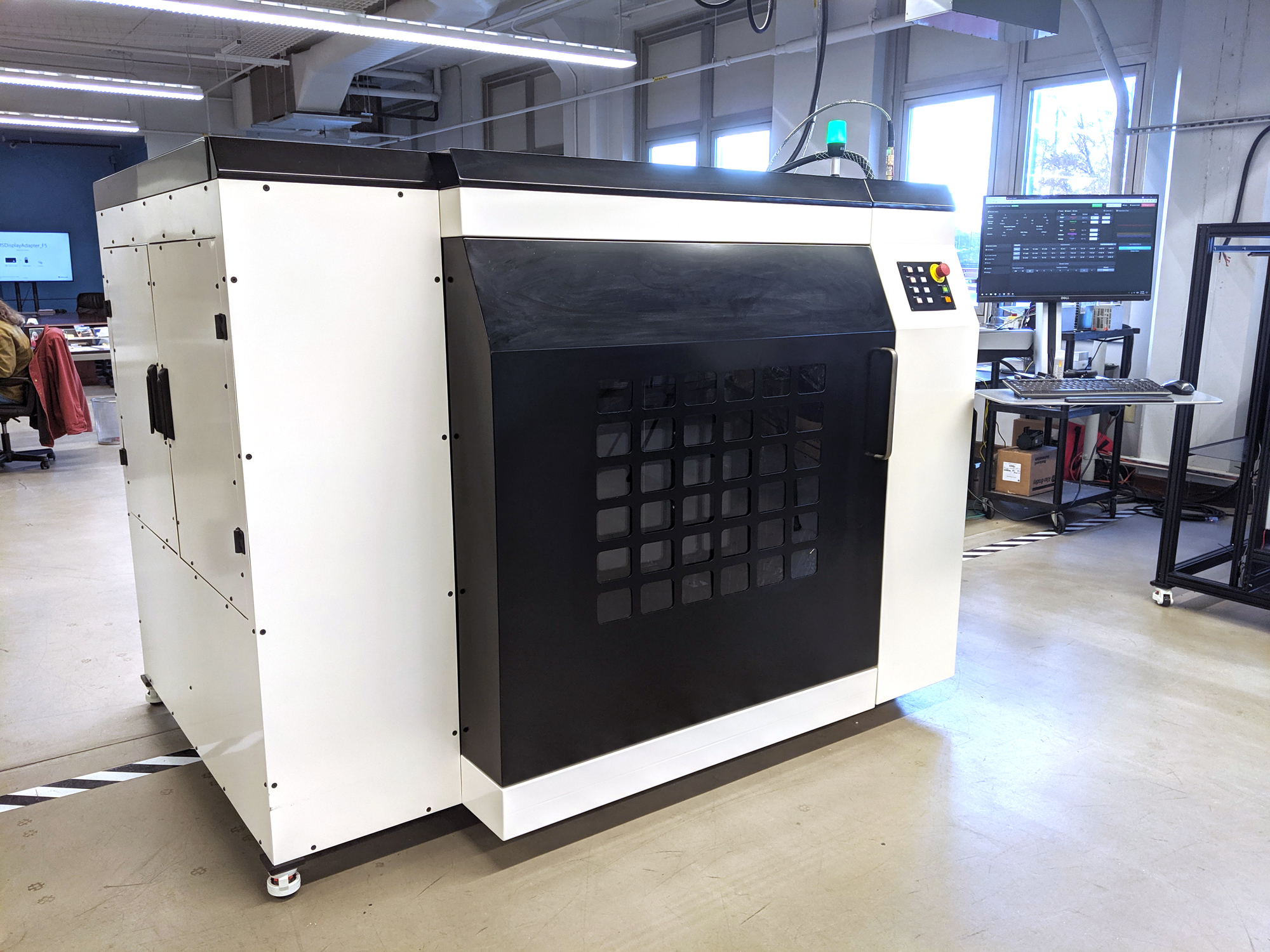

Whether you need fixtures, patterns or low-volume production, JuggerBot 3D has a machine for you.

Features

Our Patented Filament Extrusion System, also known as the Interdependent Drive System, makes it easy to process a range of diverse material options. By utilizing both push and pull forces on filament throughout the extrusion process, users can optimize extrusion rate with either flexible or brittle materials without concerns of slippage or clogging.

Streamlined Production

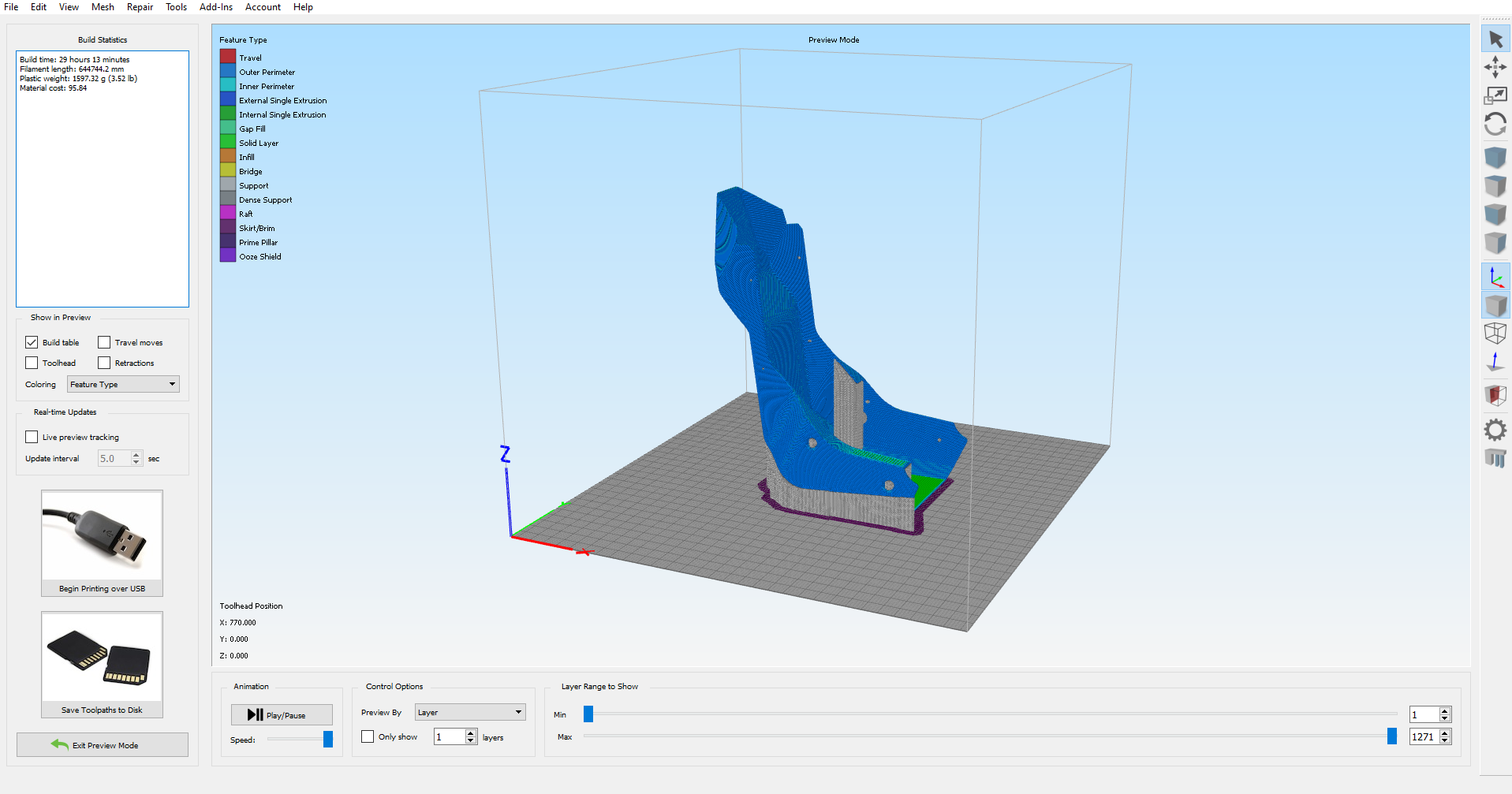

All JuggerBot 3D printers are built with an integrated workstation that includes all of the controls and software necessary for industrial printing, including professional slicing software and machine control programs that include a library of processing information.

Pre-installed remote monitoring software connected to internal cameras enables you to view printing status and control machines in real-time.

Optimal Quality Assurance

Managing the environment in which materials are stored, loaded and built is critical when processing performance thermoplastics. That’s why our filament extrusion printers are built with a material drying station, a contained loading chamber, and a build chamber design that efficiently achieves constant temperature and promotes adequate adhesion between build layers.

Easy Calibration

Setup reduction is key to optimize any piece of equipment, and the precise placement of the extruder nozzle and bed is critical to quality control. Using a program developed by JuggerBot 3D and proximity sensing technology, operators can utilize automation to simplify the bed-leveling process and repeatedly set nozzle position with ease.

Material Options

Flexible

Hard

High-Temperature